Fast and highly-capable heavy-duty alignment machine. Hunter's patented camera technology excels where it matters most.

Hunter's supercharged drive-through inspection technology is ready for heavy-duty. Sell more service. Earn more per mile. Increase safety. Reduce labor.

Sell more service. Earn more per mile. Increase safety. Reduce labor.

Quick Check® Commercial identifies all major alignment and tyre wear issues, on all axles, on all trucks.

What used to take minutes now takes seconds.

Scan every vehicle, uncover every opportunity.

That's it. That's Quick Check® Commercial.

HIGH TECH LASERS AND CAMERAS

Measure wheel alignment and tread depth

FLIGHTBOARD MONITOR

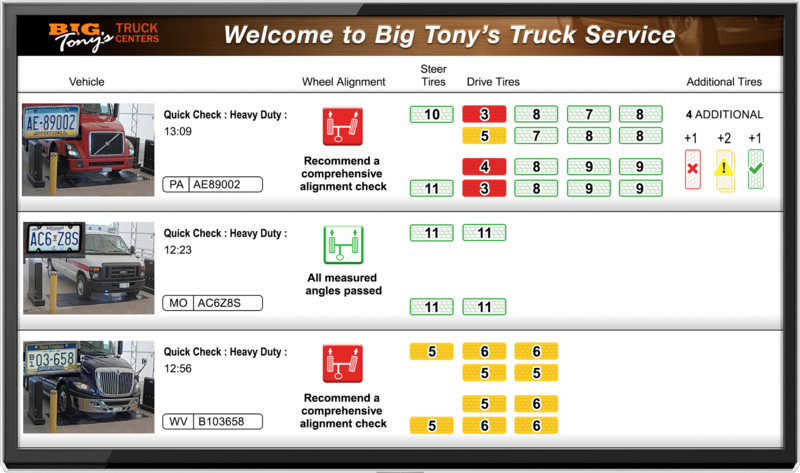

View detailed results instantly on the large Flightboard™ monitor

CUSTOMER TRANSPARENCY

Develop trust and transparency with customer through informed two-way conversation

That’s what Hunter’s Quick Check® Commercial unmanned inspection system was designed to provide. A 30-second drive-through offers an instant and effortless health check on tire tread and alignment, two of the most important safety and economic considerations for commercial vehicles.

Bergey’s Tire Centers in suburban Philadelphia has built its reputation on forming a partnership with its commercial customers and providing the best service possible. “We’re not just a repair facility,” says Steve Ford, regional operations manager. “The equipment we use is to support all that.”

Customers have long relied on Thomas Tire in Asheville, NC to take care of their HD vehicles, says co-owner Sally Thomas. In turn, Thomas relies on Hunter equipment to maintain that trust. “Our dad was always a firm believer in investing in quality, and that’s what we’ve done,” she says.

Over the course of 5 million miles, a fleet with properly aligned wheels will save approximately €50,000 in fuel and 18 million miles of tyre life.

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

High-tech lasers and cameras measure wheel alignment and tread depth. Optical and laser sensors scan camber, total toe and scrub by taking 16 measurements per tire. Results are repeatable.

View detailed results instantly on the large Flightboard™ monitor in the waiting area or service drive.

Lasers scan each tire edge to edge and provide 3-D models to illustrate the complete extent of tread wear.

Intuitive Damage-Cam interface displays vehicle information and date of service. 90-day image storage standard.

Yearly subscription charges apply.

Having responsibility for the maintenance of an entire fleet of trucks brings anxiety. Quick Check® Commercial brings peace of mind.

Simply drive the vehicle past the lasers for a complete and instant alignment and tread wear scan.

Correcting alignment issues with Quick Check® Commercial can increase fuel efficiency 2%

Misaligned wheels waste fuel on all vehicles.

For heavy-duty trucks, they waste an enormous amount of fuel

Proper alignment can extend your fleet's tyre life by 20%

Misalignment causes tyres to wear out faster

Quick Check® Commercial automatically measures tread depth and displays results in 3-D graphics

If you don't consistently inspect, a robust ROI will be slow in coming. Increase your tyre and alignment work by increasing your opportunities. Inspect for camber, total toe, scrub and tread wear in less than 30 seconds.

Actionable results automatically displayed for easy comprehension and communication.

You didn't buy an alignment system to sit against the wall.

Jump-start profitability by expanding opportunity.

Scan every axle and tire that comes into the shop.

Don’t let your alignment investment sit idle.

Boost productivity and profitability through data analysis.

Manage all your equipment data via the HunterNet® 2 software portal.

Set goals, ensure accountability and track revenue.

Actionable results are automatically displayed for easy comprehension and communication.

View previously inspected vehicles, recall printouts, and view body damage camera photos.

Get a high-level overview of your alignment machine usage trends.

View details on previously serviced vehicles.

Setup to receive daily Push Reports to keep your goals and performance in check.

GALLERY

FAQ

EXPLORE FURTHER

To give you the best experience, this website uses cookies. By continuing to use this website, you are giving consent to cookies being used.

For information on cookies and how we use them, please visit our privacy statement and our terms of use.