HawkEye® Digital Imaging Technology allows shops to perform alignments on the floor or at any lift height.

Fast results with quick setup time

Hunter Standard Alignment

/

Standard Alignment Machines

Fast results with quick setup time

Hunter offers alignment systems with simple operation and low cost of ownership. The HawkEye® and ProAlign alignment machines offer quick and efficient alignment readings through powerful software and HawkEye® imaging technology.

Features at-a-glance

- High-resolution cameras

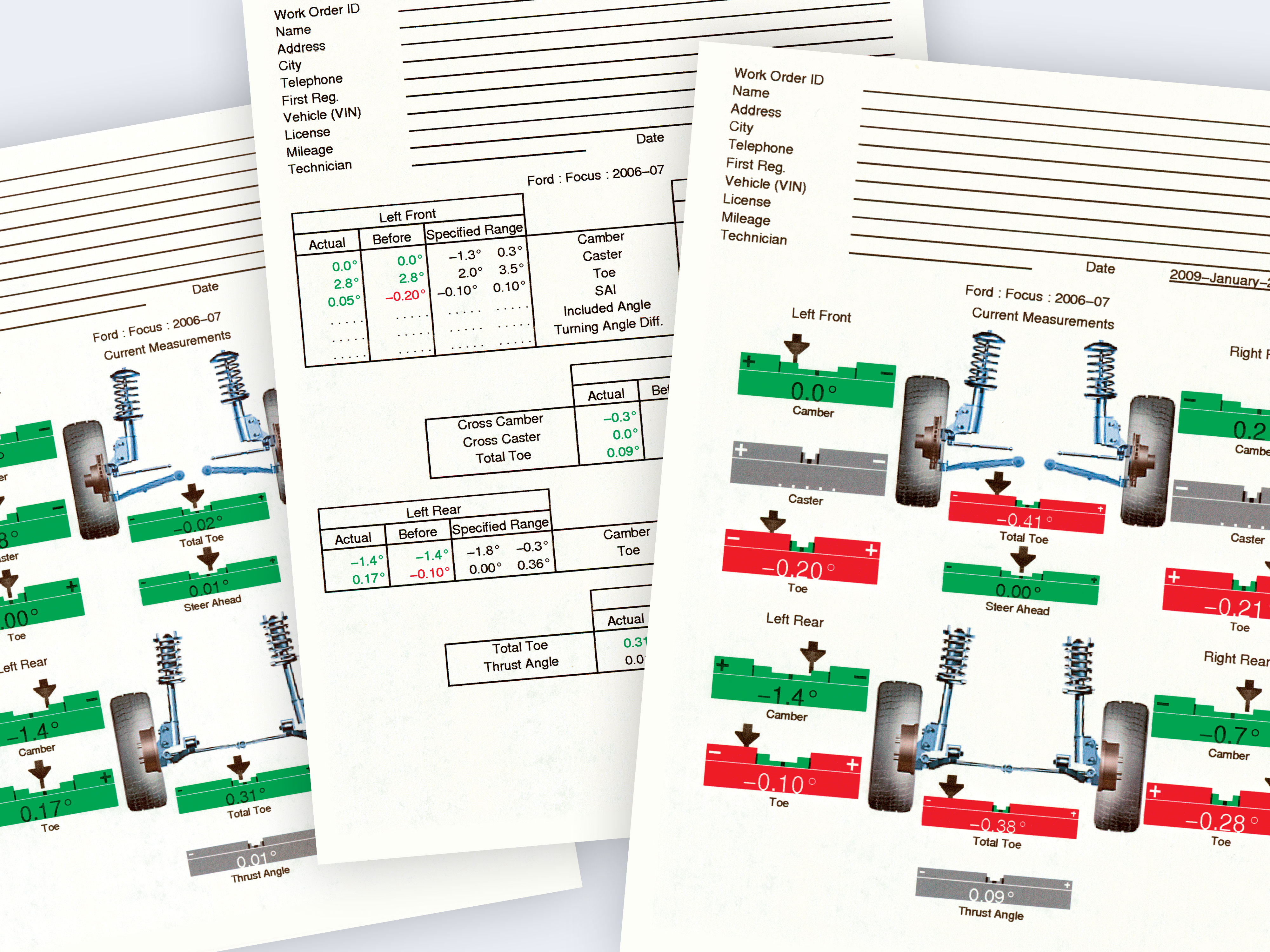

- Printouts to sell service

- Fast alignment readings

- HawkEye® digital imaging technology

Specifications at-a-glance

-

2 minuteSetup time

-

24.5 in.Maximum wheel diameter

Product family at-a-glance

HawkEye® Alignment 2-Camera System

- 3D graphics

- WinAlign® software

- 2 cameras

- Hawkeye® Digital Imaging Technology

- Self-centering adaptors

DSP700

- Fast, accurate alignment at an economical price!

- Interchangeable front and rear sensors avoid obstructions such as air dams or spoilers

- Engineered with your technician in mind

- Sensors are up to 50% lighter than previous models

Features

Perform alignments at any height

Printouts help sell service

Explain needed parts and repairs and show completed work to customers using detailed, color-coded printouts.

Easy-to-follow illustrations

Intuitive software to help guide every adjustment through easy-to-understand illustrations.

Straight Steering Wheel Every Time

Wintoe® ensures a straight steering wheel every time without repeated adjustments or using a steering wheel holder.

Simple shim installation

Shim-Select® II quickly calculates and displays the template you need for proper shim installation.

Your shop deserves the fastest, easiest system

Get 70-second alignment measurements with pinpoint accuracy with HawkEye Elite® — the most powerful wheel alignment machine on the market today.

- Get a free quote or on-site demo

- General information & questions

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Get ProAlign for heavy duty

The Hunter PT200 heavy-duty alignment system is the heavy-duty version of ProAlign, including essential features needed to perform fast, accurate alignments on trucks, buses, RVs and other heavy-duty vehicles.

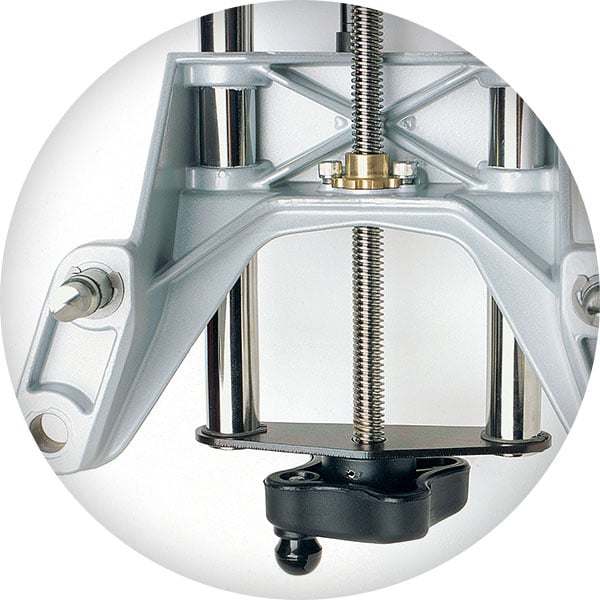

Self-centering wheel adaptors

Greater versatility helps service more vehicles

Hunter's innovative and trusted self-centering wheel adaptors ensure proper centering and durability.

- Easy to use

- Lightweight, durable construction

- Fits a wide range of wheel configurations and sizes

Adaptable rim studs

Works with specialty rims, run flat tires, and rim guard tires

Sturdy design

Durable, lightweight design provides rigidity and stability

Extended range

Coverage from 10 to 24.5 inches

Tire Grip

Fits difficult wheels

- Fastens to tires with 21 to 40 in. outside dimension

- Includes four tire clamps with protective rim sleeves

- Ideal for wheels without rim lips or with limited space between tire and rim

Extensions

Expand coverage

- Expands adaptor range up to 28 in.

- Includes 16 adaptor extensions, 4 for each adaptor

DSP700 alignment sensors

Speed and accuracy at an economical price

DSP700 alignment sensors

- Setup front and rear sensors interchangeably to avoid obstructions such as air dams or spoilers

- Pro-Comp® continuous runout compensation procedure ensures accurate alignment angles, even if wheels rotate after compensation

- Get fast and precise measurement readings for toe, toe-out-on-turns, track width and wheelbase in real-time

- Wireless, quick-recharging and lightweight design

Are you ready to hit your target alignment goals?

Having trouble deciding?

Here are some tips

- Get a free quote or on-site demo

- General information & questions

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Documents

-

Brochures

-

Specification Sheets

-

Accessories

Hunter's 3-Year Warranty

We stand beside our equipment and your purchase.

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

Explore further

Hunter service

Largest in the industryHunter deploys the largest service force of highly-qualified representatives in the industry.

- Recall specifications

- Install targets

- Capture measurements

- Review "before" results

3. Make adjustments

- Follow the adjustment instructions

- Print before-and-after results

4. Present results

- Sell more alignments

- Generate greater profits

Speed setup time with Hunter's patended QuickGrip® adaptors and high-definition targets

Fast installation

Spring-loaded clamping arms install easily — off-center placement has no affect on accuracy.

Avoid rim damage

Clamps hook tyres and protective ring provides no metal-to-metal contact.

Efficient design

Lightweight, durable and low-profile form make QuickGrip® adaptors a technician-favorite.

Fast installation

- Spring-loaded arms grip the tyre

- Thumb switch secures the clamp

- Off-center clamping has no effect on accuracy

Prevent wheel damage

- Grips tyre, not rim

- No metal-to-metal contact

- Only protective ring contacts rim

Lightweight design

- Weighs only 3.3 kg (7.4 lbs.)

- Nearly 40% lighter than previous designs

QuickComp™

Compensate all wheels and capture initial measurements in one motion.

Quick-Change Hooks

- Interchangeable hooks cover up to 940 mm (37 in.) assemblies

- One set of hooks fits most applications

Deep wheel extension

- Deep rims or protruding hubs, no problem

- Standard accessory

Reduce alignment times and increase productivity

WinToe® Adjustments

Ensure a straight steering wheel every time without repeated adjustments or using a steering wheel holder.

Control Arm Movement Monitor

Cut adjustment times in half for front-shim, dual-cam or dual-slot vehicles. Step-by-step graphics let you get it right on the first try.

Shim-Select® II

Eliminate confusing shim charts and tables. Shim-Select® II quickly calculates and displays the template you need for proper shim installation.

Easy-to-follow illustrations

Over 500 adjustment illustrations provide diagrams and instructional information of recommended Original Equipment Manufacturer (OEM) adjustment methods.